Product Description:

Introducing the DTB Crystallizer – The Digital Transformation

Booster System

The DTB Crystallizer, also known as the Dynamic Technology Booster

Crystallizer, is a revolutionary advancement in the field of food,

beverage, and chemical production. With its 1-year warranty and

steam heating method, the DTB Crystallizer provides a reliable and

efficient way to produce crystal-clear results. This cutting-edge

technology is ideal for achieving a top-quality product with

minimal effort.

The DTB Crystallizer not only offers a reliable and efficient

method for producing crystal-clear results, but it also provides a

highly customizable solution tailored to your specific production

requirements. Thanks to its advanced digital transformation booster

system, the DTB Crystallizer is capable of delivering crystal-clear

results with maximum efficiency and speed. With its

state-of-the-art design, this innovative system ensures that you

can achieve the highest quality product with minimal risk.

The DTB Crystallizer provides an ideal solution for the food,

beverage, and chemical industry. With its 1-year warranty and steam

heating method, this reliable and efficient system is designed to

help you achieve crystal-clear results with minimal effort. Thanks

to its cutting-edge technology, the DTB Crystallizer is the perfect

solution for achieving a top-quality product with maximum

efficiency and speed.

Features:

- Product Name: DTB Crystallizer

- Name: Digital Technology Booster Crystallizer (DTB Crystallizer)

- Application: Food, Beverage, Chemical, Etc.

- Capacity: 50-50000L/H

- Warranty: 1 Year

- Temperature Control: Automatic/Manual

- Dynamic Transformation Booster: Data Transformation Booster System

Technical Parameters:

| Model | GLDTB-01 | GLDTB-02 | GLDTB-03 |

| water evaporation capacity (t/h) | 0.1-2 | 0.5-10 | 2-20 |

| input concentration (%) | according to material |

| steam pressure (Mpa) | 0.4-0.8 |

| evaporation temperature (℃) | 45-90 |

| Steam consumption (t/h) | 0.65 | 0.38 | 0.28 |

| Cooling water cost (t/h) | 2-40 | 7.5-150 | 25-250 |

Applications:

Geling GLDTB DTB Crystallizer – An Ideal Solution for Food,

Beverage, and Chemical Production

Geling's GLDTB DTB Crystallizer is a state-of-the-art

crystallization system that allows you to produce high-quality

crystallized products with precision and consistency. It is

designed to offer dynamic transformation booster (DTB)

crystallization technology for maximum efficiency in

crystallization processes. This advanced technology enables users

to control temperature, pressure, and other variables quickly and

accurately, ensuring optimal output quality.

The GLDTB DTB Crystallizer is ideal for food, beverage, and

chemical production. It is equipped with an advanced

computer-controlled system for automatic or manual temperature

control. The system also features a user-friendly interface for

easy operation and control. Additionally, the GLDTB DTB

Crystallizer is easy to install and maintain, and it comes with a

1-year warranty.

With its advanced DTB crystallization technology, the Geling GLDTB

DTB Crystallizer is an ideal solution for food, beverage, and

chemical production. It enables users to quickly and accurately

control temperature, pressure, and other variables to achieve the

highest quality output. This system also comes with an easy-to-use

interface and a 1-year warranty for added peace of mind.

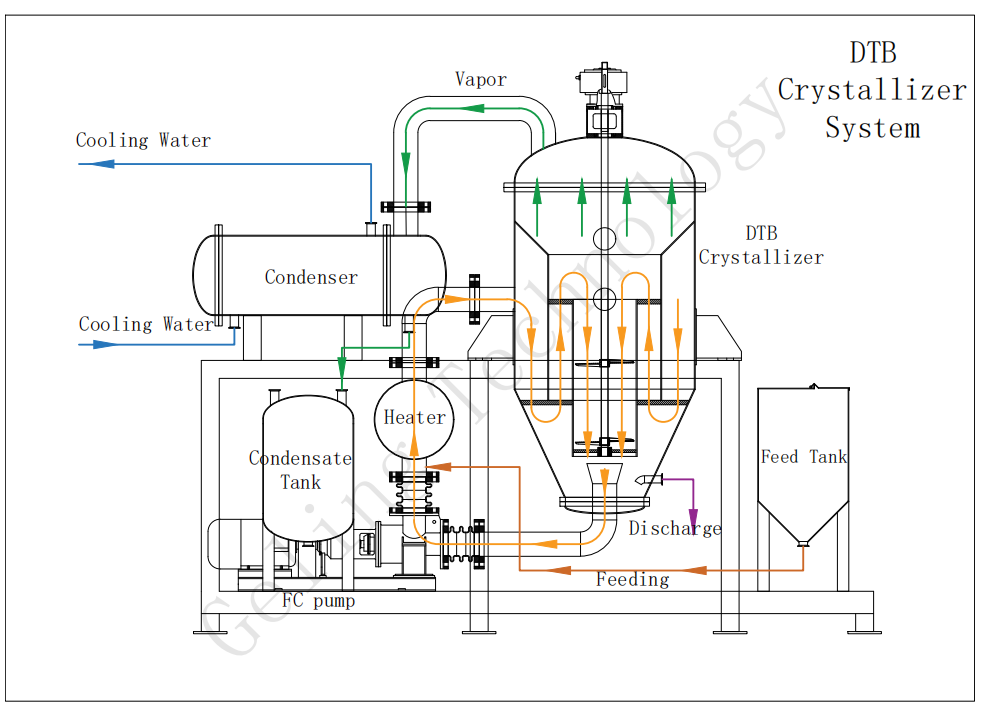

Process flow:

Packing and Shipping:

Packaging and Shipping for DTB Crystallizer:- The product will be packaged in a cardboard box.

- The box will be well sealed to prevent damage during shipping.

- The product will be shipped via a secure shipping method, such as

FedEx or UPS.

FAQ:

Q1: What is DTB Crystallizer?

A1: DTB Crystallizer is a premium brand product from Geling, with

model number GLDTB, originating from Shanghai. It is a

crystallization system specially designed for the chemical

industry.

Q2: What are the advantages of DTB Crystallizer?

A2: DTB Crystallizer offers a wide range of features and benefits,

such as high efficient cooling, efficient stirring, and easy

maintenance. It also offers excellent cost effectiveness and a long

service life.

Q3: What is the working principle of DTB Crystallizer?

A3: DTB Crystallizer is based on the principle of crystallization,

which is a process of separating out solid crystals from a solution

of two or more substances. The crystallization process involves

cooling the solution to a temperature at which the desired solids

will precipitate out of the solution.

Q4: What is the application of DTB Crystallizer?

A4: DTB Crystallizer can be used in a variety of industries such as

food, pharmaceutical, chemical, and metallurgical industries. It is

suitable for crystallization of both organic and inorganic

compounds.

Q5: How to operate DTB Crystallizer?

A5: Operating DTB Crystallizer is easy. Simply set the temperature

and stirring speed, and the crystallization process will begin. The

crystallization process can be monitored and adjusted in real-time

via a touch screen monitor.